How to weld the film?

What is welding?

Welding is the process of connecting separate sections of material. Welding is resorted to if the proposed size of the film does not fit the required dimensions. For example, if you need a 10x15 meter pond.Film welding instructions

What do you need for welding?

To weld we will need:- iron, blow dryer or soldering iron,

- wooden bar,

- lining: paper, baking sleeve, cellophane, etc.,

- film.

Film welding process

1. Space preparationPlace something soft and dark-colored, such as a black cloth or black porous rubber, on the surface where the welding is done. Such "bedding" will ensure fast and high-quality melting of the upper material and the lower cloth. To prevent the film from sticking to the fabric (rubber) and the heating device, put cellophane, fluoroplastic film, or, if there is nothing like that at hand, oiled or waxed paper between them.

2. Layout of the welding film

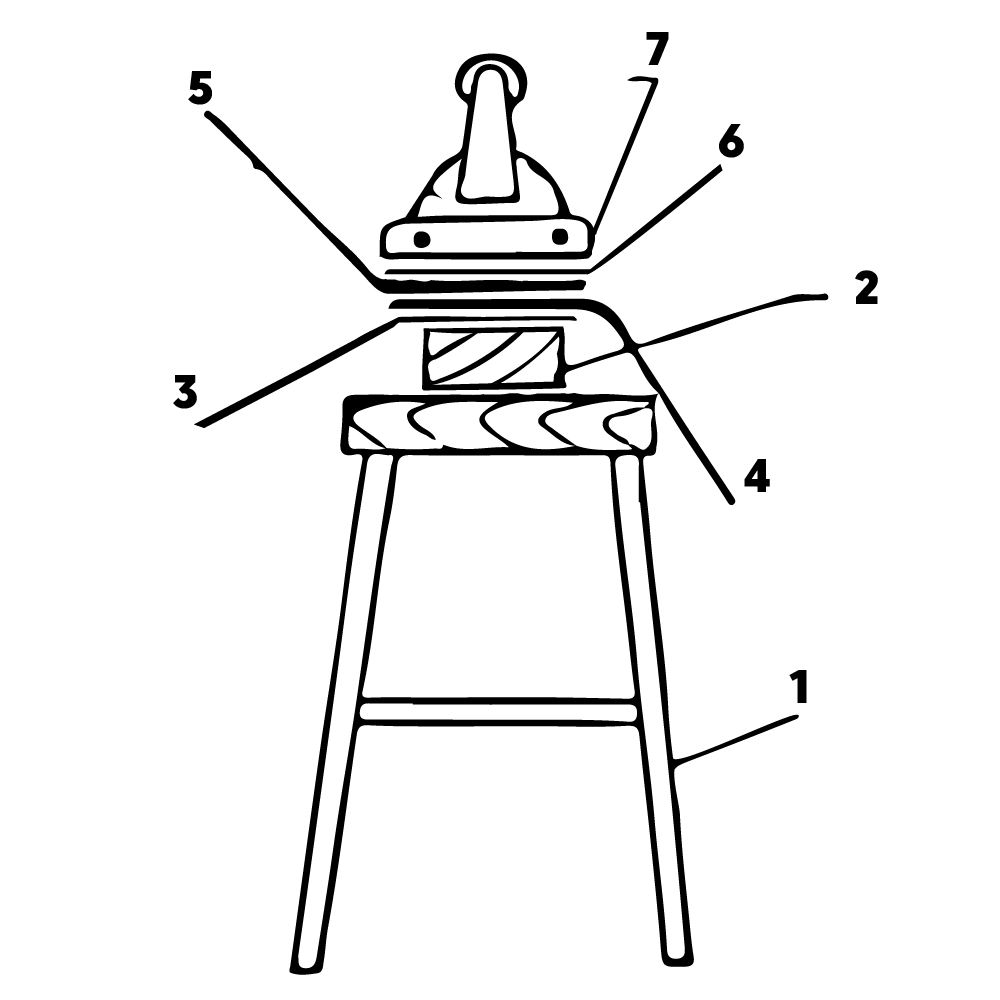

1 – desk (stand); 2 – rail; 4, 5 – film sheets; 3, 6 – lining; 7 – iron

For welding, the edges of the film are laid on top of each other with an overlap. The width of the overlap is chosen depending on the purpose of the film. As a rule, for welding:

- for greenhouse films a 1-3 cm overlap and one weld is enough;

- films for waterproofing and construction of ponds overlap increase to 8-12 cm and make 2-3 welds.

3. Film welding

Once all the layers are laid, you can proceed directly to the welding. The heating equipment should be turned on to maximum power and wait for the heat to build up.

The speed at which you need to run the blow dryer, soldering iron, or iron is chosen experimentally on small film samples. If you take too little time to weld the film, the seam may not be airtight, and if you take too long, you can damage the film.

Following these simple recommendations, you can weld almost any product: (case, cape, etc.), which will have an airtight, durable and reliable seam.

- Комментарии